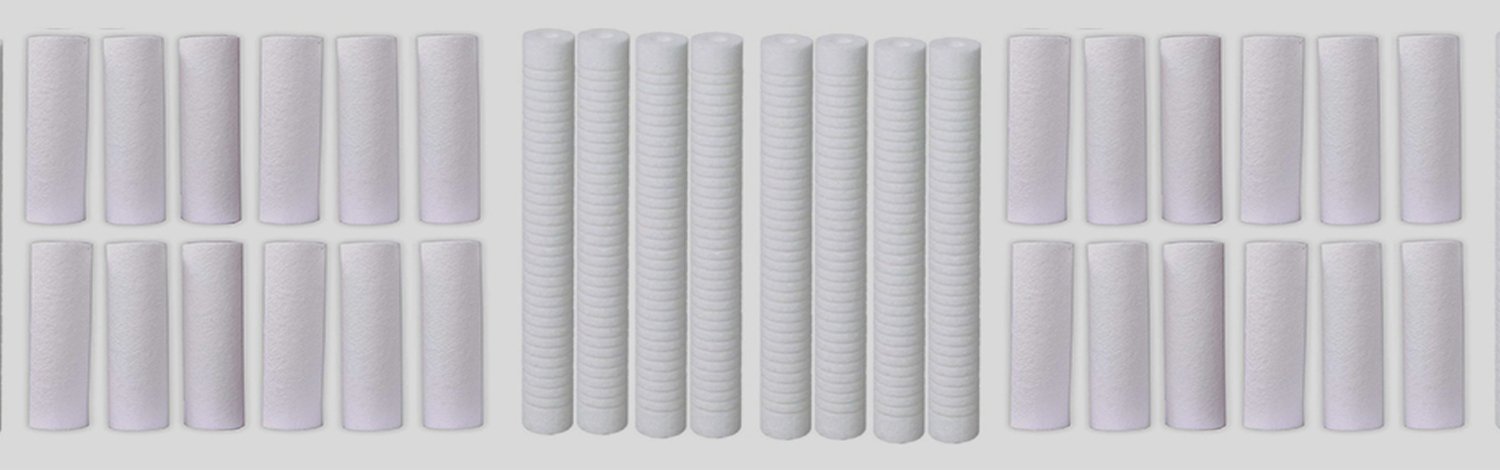

Spun Cartridge

Spun bonded filter cartridges are made up of 100% polypropylene fibers. The fibers have been carefully spun together to form a true

gradient density from outer to inner surface. Filter cartridges are available with core & without core version. The superior structure

remains integral even under severe operating conditions and there is no media migration. Polypropylene fibers are blown

continuously on central molded core, without any binders, resins or lubricants.

Salient Features of Spun Bonded Filter Catridge

Free of surfactants, binders and adhesives

Excellent flow with low pressure drop

High dirt holding capacity

100 % Polypropylene for wide chemical compatibility

High strength & pressure resistance

Nominal & absolute filtration rating

Applications of Spun Bonded Filter Catridge

Food & Beverages

Pharmaceuticals

Fine Chemicals

Petrochemicals

Cosmetics

Water Treatment

Metal Finishing

Specifications

Sizes: 10”, 20”, 30”, 40” long

Micron Rating: 1, 5, 10, 25, 50, 75, 100

Inner Diameter: 25mm, 28 mm, 48 mm

Operation of Spun Bonded Filter Catridge

Unfiltered fluid passes through depth filter matrix and enables the progressive retention of finer particles, which provides high efficiency, high dirt retention & long filter life. Fluid flows from outside to inside through filter media. Particulates are held securely in the filter matrix and clean fluid flows to the downstream side of cartridge.