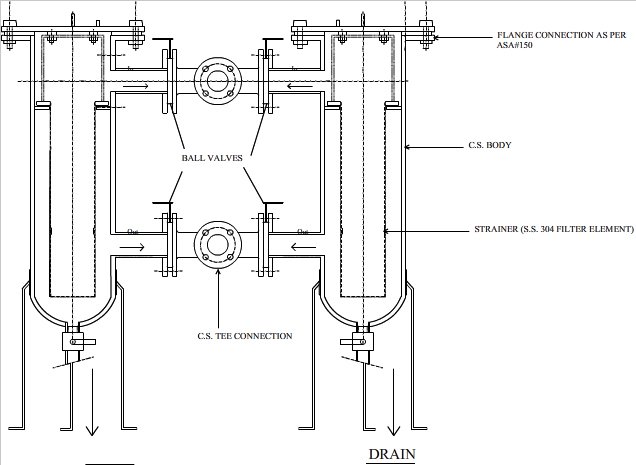

Duplex Filters

Duplex basket filter & strainer permits continuous operation because flow can be switched back and forth between two filter

sections. This allows one side to be serviced while the other is in use. Normally duplex basket filters are separated with three

way ball valves or two way ball valve/ butterfly valve connected with equalization tee, between two baskets filter housing.

Operation of Duplex filters

Unfiltered liquid enters the basket housing and passes down through them. Duplex Basket filters & strainers are normally supplied with nut/bolt arrangement at the top of filter element. This will ensure any type of bypassing & confirm the position of basket, even in case of reverse flow. Fluid bypass around the basket is prevented by an optional O’-Ring seal between the basket rim and the housing inside diameter. The valves provided along with the assembly make sure you get intermittent operation.

Salient Features of Duplex filters

No shutdown time

Online change over to either of strainer vessels

Dimensionally flexibility due to fabricated construction

Both inline & offline connection available

All housings made from SS 316 L, SS 316 & SS304 are mirror

polished to resist adhesion of dirt and scale

Carbon steel housings are Epoxy coated & finally painted with two

coats of synthetic enamel

High temperature & high pressure design are available

Design Features of Duplex filters

Custom modifications available to suit customers required

Strainers designed to meet requirement of ASME section VIII div-I

Ball valve, gate valve butterfly or other valves can be provided as

per requirement

304 / 316 perforated screens / mesh are standard

Drain vents & differential connection are standard and are

furnished with plugs

Material of Construction

of Duplex filters

Carbon steel (All Grades)

Mild Steel

Caste steel

S.S. 304

S.S. 316

S.S. 316 L

Application of

Duplex filters

Process Industries

Chemical Industries

Oil & Gas Industries

Process Industries

Chemical Industries

Oil & Gas Industries

Size

Range

Connection Size – 1’’ to 16’’

Class #150 to #300